| |||||

|

|

||||

Alloy263(2.4650) Product Introduction:

Alloy 263 has up to 816 ˚ C's high strength and up to 982 ˚ Excellent antioxidant properties of C. This alloy has good formability, ductility, and weldability. In the annealed state, this alloy has excellent ductility and is easily formed by cold working.

Tungsten gas shielded welding usually uses argon gas as a shielding gas. Argon+5% hydrogen has been used. Alloy 263 base material is usually rapidly cooled for welding under annealing conditions of 1148 ° C. After welding, the components can be aged for 8 hours under air cooling at 798 ° C. Repair welding of alloy 263 components can be carried out under age hardening conditions.

Common grades of Alloy 263:

N07263, 2.4650, Alloy 263, Nimonic 263

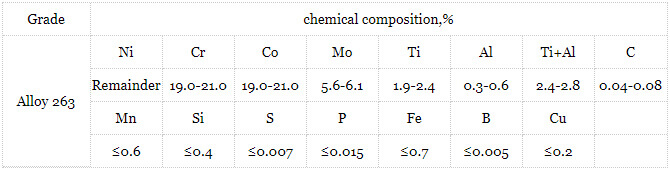

Chemical composition under AMS5872 standard:

The execution standards for Alloy 263 include:

Standards: AMS 5966, 5886, 5872, 5872E, RRMS 33031/1 (MSRR7035), BS HR10.

Alloy 263 combines multiple characteristics, making it suitable for various manufacturing components in aircraft and land-based turbine applications.